What is Rubber?

What is rubber?

Rubber is an elastic, flexible and resilient material that can be created by extracting the sap from latex trees (Natural Rubber) or obtained from the use of petroleum and gas (Synthetic Rubber). Which is most commonly used to make tyres.

One of the most versatile and multi-purposed materials on the planet, Rubber has become a staple that can be found in or a part of most of our household items. You can find rubber in any room, any vehicle and most objects. In fact, you're probably looking at something that has rubber attributes at this very moment.

Waterproofing and Rubber Mastication

Prior to the 1800s, there were limited uses for rubber. However, popularity and interest in the material slowly increased and in 1823 a waterproof fabric was patented by inventor and scientist Charles MacIntosh, the son of a well-known fabric dyer in Glasgow. He achieved this by layering pieces of rubber between two pieces of wool cloth. Despite still stiffening in the cold, and having a distinctive rubber smell, this invention addressed the issues associated with the use of rubber in hot temperatures. Thomas Hancock, a self-taught engineer from Wiltshire who was also working on using rubber to waterproof fabrics, took out a patent for artificial leather. He went on to invent the Masticator machine, which would break up the rubber into a warm mass of homogeneous materials which could then be easily shaped, even in cold weather. Little did these gentlemen know over the pond, another Charles was working on something that would revolutionise the use of rubber.

Who invented vulcanisation?

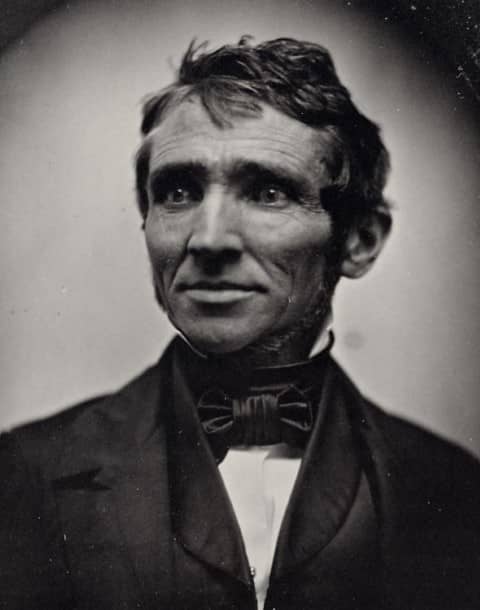

Vulcanisation was invented and patented by two inventors in two different countries. Thomas Hancock discovered vulcanisation in the UK and Charles Goodyear discovered it in the USA. Goodyear discovered vulcanisation when he accidentally dropped natural rubber and sulphur on a stove. Discovering the material appeared smoother and harder with improved elasticity, Goodyear realised he was onto something.

Both inventions, the Masticator and waterproof fabric, made rubber more practical and increased its widespread use. As Hancock continued to work on ways of improving the properties of rubber, so did Charles Goodyear, another self-taught scientist and engineer working in the USA. Goodyear was down on his luck, he was bankrupt and away from his family courtesy of being in and out of debtors jail. He did however have a good rapport with the prison guards. So much so, they allowed him to conduct experiments during his incarcerations. This began a string of trial and error experiments mixing latex with random substances in the hope that the rubber becomes less prone to decomposition. In 1839 Goodyear accidentally dropped latex mixed with sulphur on a hot stove and that blunder proved to be a blessing in disguise. The happy accident made the compounded material smooth and cured. Scientifically speaking he was able to manipulate the molecules within the latex causing polymerisation of the monomers, turning them into polymers, creating a long chain thus strengthening the material. The rubber was no longer malleable and when compressed it bounced back to its original shape.

If you're looking for a more scientific view of Rubber. Check out the Science of Rubber.

Both Goodyear and Hancock successfully patented these processes in their respective countries which involved heating rubber with sulphur at high temperatures causing the 'cured' rubber to become more stable, tougher, and more resistant to hot and cold temperatures. Goodyear named this process vulcanisation after the Roman God of fire, Vulcan. Following the success of vulcanisation, many rubber trees were planted in various tropical and far eastern countries that the western world was occupying. Sadly, Goodyear would never profit from his discovery, he spent many years embroiled in a legal battle with Hancock to be recognised as the sole inventor. Unsuccessful, he passed away in debt and would end up making his fortune posthumously with the release of his memoirs and the decorated Charles Goodyear reward.

The process for vulcanisation was later improved in 1912. U.S chemist George Oenslager worked alongside David Spence and discovered a faster way to vulcanise rubber by using organic carbon-based accelerators. Oenslager will go on to introduce carbon black to the world while Spence would help bring isoprene compounds to key markets.

Who invented the tyre?

Robert William Thomson discovered the pneumatic tyre in 1845 and was handed the patent in 1846, whilst being only 23 years old. The tyre was designed to reduce noise and improve comfort for the passenger or rider. However, his efforts turned to frustration as the materials he needed were not readily available. Thomson made the decision to return to improving the solid rubber tyre.

Later on, in the 1800s fellow Scotsman, John Boyd Dunlop was watching his son playing on his tricycle with great difficulty due to the solid rubber tyres. Unbeknownst to Dunlop, Thomson already had the patent, he came up with the idea of an improved pneumatic tyre in 1888. He glued two rubber strips together like a tube and wrapped it around the wheels of the tricycle, then injected air into the rubber with a football pump. Dunlop sold the rights to his invention and the use of his name in 1895. He played no further part in the company which bore his name. The company bought many of the rubber tree plantations in southeast Asia as the demand for pneumatic tyres for motor vehicles increased exponentially, the automotive industry took off.

Natural and synthetic rubbers

Latex is a natural resource that can be botanically sourced from trees. As natural rubber was developed and processes were invented throughout the 1800s and early 1900s, rubber became an increasingly valuable material. Synthetic rubber was experimented with around the same time as its counterpart but was used more once the demand and price of Natural Rubber increased.

What is synthetic rubber?

Synthetic Rubber is created by taking manufactured rubber and combining it with another element or compound. The first instance of Synethetic Rubber came in 1876 when Gustave Bouchardat mixed Isoprene (taken from natural rubber) and hydrogen oxide gas which gave off the same effect as rubber.

As the demand for rubber increased, chemists attempted to develop new synthetic materials that could recreate the properties of rubber. The following line of synthetic rubbers was developed in Germany and Russia during the First World War. However, these rubbers could not compete with natural rubber on either quality or price.

Despite the unpromising first attempts, interest in synthetic rubbers returned in the mid-1920s as the high demand for rubber led to sharp increases in price. By 1935 Germany had developed two successful synthetic rubbers known as Buna rubber. Synthetic rubbers were developed further during the second world war as natural rubber became difficult to source. In 1941 the production of synthetic rubber in America was 8000 tonnes. By 1945 the demand had vastly increased to 820,000 tonnes. Nowadays, synthetic rubbers account for over 50% of world rubber consumption. Commonly used synthetic rubbers include Styrene-Butadiene (SBR), Ethylene Propylene Diene Monomer (EPDM) and Polychloroprene, commonly referred to by its' trade name, Neoprene (CR). Check out our selection of Natural and Synthetic rubbers.

Rubber chemical formula

To create synthetic rubbers, scientists aimed to recreate the hydrocarbon polymers found in natural rubber latex. Michael Faraday, the pre-eminent English Scientist studied natural rubber in the 1800s and found its chemical formula to be(C5H8)n along with 2-4% protein and 1-4% acetone-soluble materials. As natural latex contains only hydrogen and carbon atoms, these polymers can be created using petroleum hydrocarbons as the basic raw material.

Synthetic rubber is primarily made using Naphtha, which is a by-product of refining oil and coal. For example, SBR, a widely used synthetic rubber, can be produced by extracting styrene and butadiene from petroleum. These petroleum by-products can then be combined to form synthetic latex, which is then coagulated by acids and dried, similar to the process for natural latex. This way, scientists are not only able to reproduce rubbers which are found in nature but can create completely new materials.

Can synthetic rubber replace natural rubber?

SBR has comparable properties to natural rubber and could be easily used as a replacement for natural rubber. Nitrile rubber went a step further in addressing the major downfall of natural rubber, which is its vulnerability to fuels, oil and non-polar solvents. This version of synthetic rubber has a much better oil resistance than natural rubber and can therefore be used in applications where the rubber is in contact with oils or fuels.

Each synthetic rubber has its own unique properties, which make it particularly suited for certain applications. The continued development of synthetic rubbers has opened the door for rubbers being used in an even wider variety of products than before. Nowadays, synthetic rubbers account for over half of the rubber produced annually and are used in many applications.

Natural rubber vs. synthetic rubber

Both natural and synthetic rubbers have good qualities, depending on the particular application or requirement you need them for. Although some synthetic rubbers outperform natural rubber in areas such as oil resistance or thermal stability, none have the required properties to replace natural rubber completely. Compared to most synthetic rubbers, natural rubber is much more resilient and has more “spring back”. Natural rubber also has excellent resistance to heat build-up which is difficult to replicate in synthetic rubbers.

Is rubber a plastic?

It's easy to get mixed up with both plastic and rubber as they are both compounds and polymers. Although both are considered polymers, rubber is also labelled as an elastomer due to its elastic properties. The major difference between plastic and rubber is that plastic has plasticity and rubber has elasticity. Elasticity means that when rubber is subjected to a heavy load it will “spring back” to its original shape. Whereas plasticity means that the material will remain deformed when subjected to a heavy load, making plastic exceptionally good for moulding.

Rubber vs. plastic

To highlight the difference between the two materials here's the tale of the tape.

| Rubber | Plastic |

|---|---|

| Elastomer/Polymer | Polymer |

| Elasticity - returns to its shape when structure is compromised | Plasticity - remains deformed when structure is compromised, great for moulding |

| Made industrially and naturally (trees) | Made industrially |

| Produced naturally inside trees and synthetically using natural gas/petroleum | Produced with crude oil |

| Multiple properties between natural and synthetic rubber | Plastic is synthetic |

| Can be toxic | Less toxic |

| Natural Rubber decomposes quicker than Synthetic | Takes a long time to decompose |