Rubber for the Civil Engineering Industry

Our role in the civil engineering industry

Civil engineering is easily one of the most dependable and prominent industries in world. This sector develops and maintains the foundations that keep our cities and towns together. Along with construction these two industries equate for 28.3% of GDP. It has a market size of £6.9 trillion and is expected to grow by 5.7% to £10.01 trillion by 2028.

We have supplied rubber components and products used on the smallest developments and the most identifiable and impressive landmark structures in the UK.

Need a problem solving? Whether it’s bespoke glazing seals or bumper protection we have the expertise and UK manufacturing facilities to source high quality and cost-effective civil engineering rubber solutions.

Rubber applications for civil engineering

The Civil Engineering industry is always in need of rubber, here is a selection of popular applications:

- Building extrusions for electrical cables

- Industrial hosing for heavy machinery

- Vibration dampening for bridges

- Bumpers for bridges and roads

- Fenders for bridges and roads

- Work site non-slip matting

- Underground electrical cable extrusions and seals

- Impact absorbing fendering for barricades

- Fendering and bumpers for car parks

We have designed, manufactured and supplied rubber seals, sheet, matting, joints, trims, protectors and access ladders to the civil engineering sector. These highest quality rubber products have helped architects, designers, groundwork subcontractors, surveyors, installers, construction giants and facilities management companies.

Our CapabilitiesRubber applications for civil engineering

The Civil Engineering industry is always in need of rubber, here is a selection of popular applications:

- Building extrusions for electrical cables

- Industrial hosing for heavy machinery

- Vibration dampening for bridges

- Bumpers for bridges and roads

- Fenders for bridges and roads

- Work site non-slip matting

- Underground electrical cable extrusions and seals

- Impact absorbing fendering for barricades

- Fendering and bumpers for car parks

We have designed, manufactured and supplied rubber seals, sheet, matting, joints, trims, protectors and access ladders to the civil engineering sector. These highest quality rubber products have helped architects, designers, groundwork subcontractors, surveyors, installers, construction giants and facilities management companies.

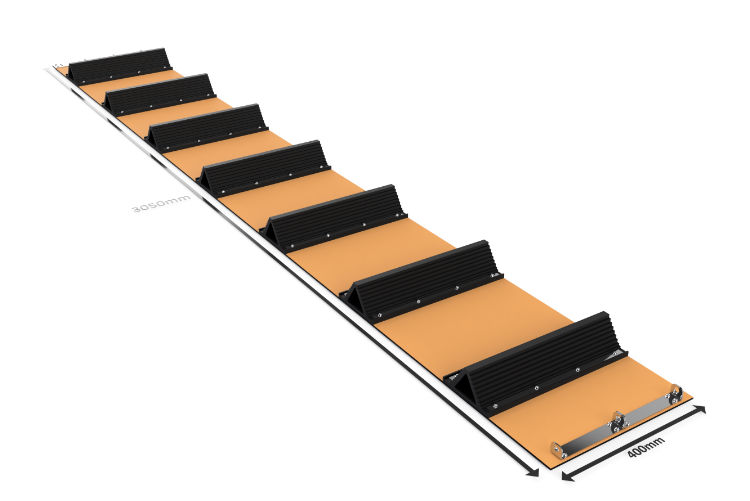

Our CapabilitiesNo more slips with Rollaway portable safety stairs

The Rollaway has been designed to prevent slips and falls in outdoor settings, helping workers safely navigate slippery or uneven surfaces like banks, ditches, quarries and hills. Your Rollaway will be custom made exclusively by us and can be produced at any length.

More about The Rollaway

Civil engineeringExtrusions for electrical cabling

Walker Rubber produces numerous extrusions to house your electrical cabling. With over 1000 standard profiles to choose from and custom-made extrusions available, the possibilities of endless. Our extrusions are good insulators and will protect your cables from becoming frayed or damaged.

Civil engineeringAnti-slip worksite rubber matting

Making working more pleasant with our rubber flooring. Lay them onto cold concrete floor and feel the difference with a cushioned surface making walking around the workplace comfortable. Workshop rubber flooring provides both insulation for those working with electrics and anti-slip protection for workers moving in a fast fashion to complete their tasks efficiently.

Did you know...?

To collect robust and reliable data on traffic movements, companies need flexible and durable equipment that is properly protected and able to withstand harsh condition and various conflicting measures. We designed and manufactured an extruded profile in our own factory in Norwich. This only took a matter of days enabling our customer to deploy their safe and secure cable management system both quickly and effectively.

The Walker Rubber Difference

Delivery

Rubber products manufactured to order with industry leading turnaround times.

Support

Not quite sure what you need? Our team are on hand to provide fast, high-quality expertise with years of experience to back it up.

Service

Your journey with us starts in sales. Like our exceptional manufacturing lead times, our sales team is no different. They will guide you through the process every step of the way. We are proud to say 90% of enquiries are quoted on the same day ensuring there is no delay in getting your project with us underway.

Quality

With our right first-time ethos, combined with only using premium materials from trusted sources, the quality of our rubber products are the best in the business.

Our Capabilities

Extrusion

We are experts in the manufacture of rubber extrusions. Our limitations are very small we can produce extrusions from 1m to 10,000m in length or 1mm to 300mm across.

Rubber ExtrusionsGaskets

Our selection of cutting machinery enables us to be accurate and precise, meeting the required specifications for our customers.

Rubber GasketsMouldings

Most moulding requirements are unique to each customer. We supply a comprehensive range of mouldings in a variety of compounds: EPDM, Neoprene, Natural, Nitrile Silicone, Viton, Polyurethane and TPE.

Rubber Mouldings

Bonding

One of our more unique capabilities. We can bond together multiple types of rubber sheet to create your ideal material.

Rubber Bonding

Tooling

We have the capability to manufacture tooling inhouse, turning your ideas into reality with a short but cost-effective turnaround

Rubber Tooling