Cutting Rubber Parts

What are the techniques for cutting rubber?

There are several industrial cutting techniques commonly used to produce rubber products. Some are better suited for thicker materials, while others can produce higher tolerances. Choosing the right cutting method for your application requires an understanding of each method as well as the material being cut. The most popular methods of cutting rubber are:

- Manual cutting

- Die cutting

- Water jet cutting

- Laser cutting

What is manual cutting?

Manual cutting is the simplest way to cut industrial rubber products, often orchestrated with a box cutter or bladed knife. Typically, an employee will position the material on a work surface and create a stencil or template for use during cutting. With edge trim that contains metal wire, guillotine cutting is used instead.

The cost effectiveness of the manual cutting method is completely dependent on the skill of the employee. It might seem cost-effective at first, but after taking the true cost of rework and material waste into consideration, this is rarely the case. Manual cutting cannot compete with other methods when it comes to producing products with tight tolerances and precise shapes. It also increases the risk of employee injury.

What is die cutting?

The die-cutting process is very straightforward. Steel dies are created and used to stamp out parts like a cookie cutter. There are three standard methods within the die cutting method that are used in industry, these are the flatbed, rotary and digital die cutting methods.

The digital die cutting method largely differs from the other two in that it does not actually involve a die, but a tool similar to an oscillating blade that cuts out the desired shape.

Flatbed die cutting is slow but can process thicker materials than the other two methods. Rotary die cutting is faster than the other two methods and is very accurate, but initially expensive.

The digital die cutting method is also initially very expensive but is highly accurate and, in contrast to the other two methods that are limited to the available dies, can cut any shape by simply programming it to do so.

The die cutting method can be used for:

- Through cutting: Cutting through the entire material so the piece can be separated from the whole material.

- Scoring: This process does not cut through the whole material. It just indents or partially cuts into the material to make it easier for folding and other processes.

- Kiss cutting: This cut is specifically for adhesive-lined materials because it goes through everything but the backing material layer.

- Perforating: Creates a series of punch-through holes so the piece will not be fully removed from the whole material.

- Broaching: When the material is particularly thick, it may require this specialized form of die cutting.

Just like the manual cutting method, the die cutting method puts pressure on the material in such a way that can cause beveling and edge distortions especially with softer elastomers. This happens no matter which type of die is used.

For prototyping and low-to-medium volume production, especially when tighter tolerances are required, the laser and water jet cutting methods make more sense.

What is water jet cutting?

This technique uses extremely high-pressure water streams to precisely cut shapes out of a given material, and as such does not require tooling. This can:

- Eliminate costs

- Speed up prototyping

- Reduce lead times on new production

Water jet cutting does not deform rubber materials in the same way that manual and die cutting does, so, cut edges are not rough or beveled and tight tolerances can be achieved. Water jet cutting can also create notches, angles, holes, dovetail cuts, and other part features.

For cutting thicker and harder materials, an abrasive sand can be added to the water to increase the cutting capabilities of the water jet cutting method.

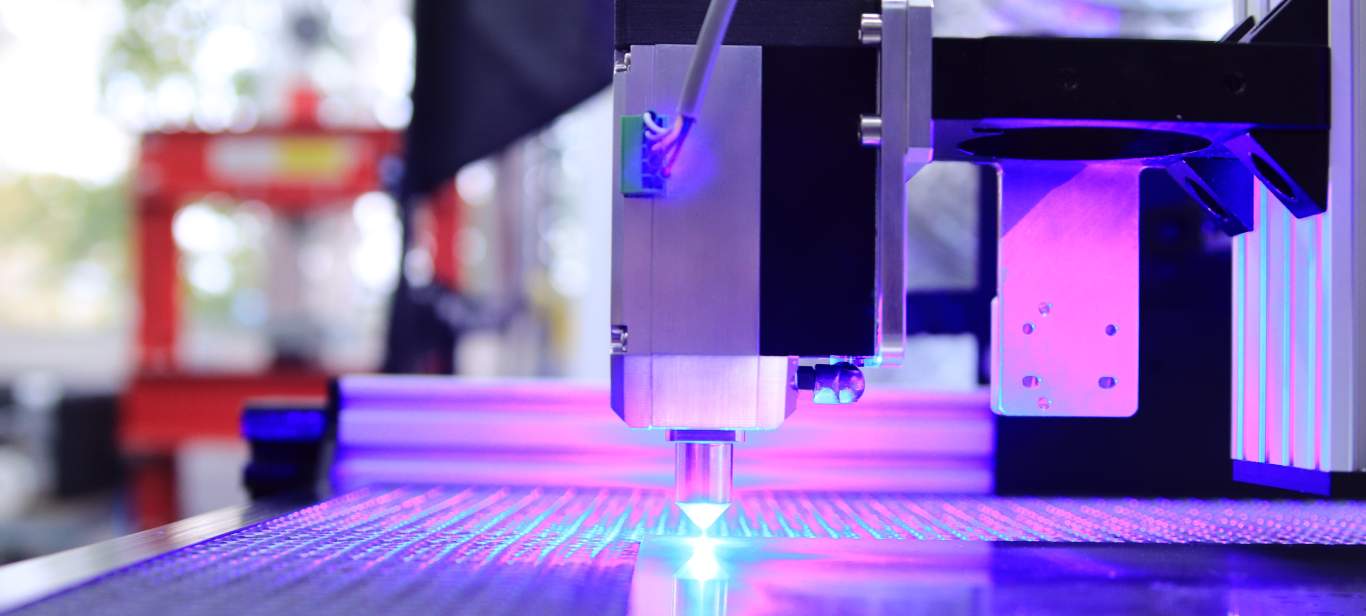

What is laser cutting?

A direct and focused laser beam can cut at amazingly high detailed levels, which means very tight tolerances even on the smallest of pieces. This cutting method is particularly useful on thin rubber sheets or compressed fibres and adhesives.

These cuts produce very clean and smooth edges being lasers can reach a high enough heat that could literally vaporise the material it is going through.

A laser cutting machine can be programmed with highly detailed plans and still deliver a quick turnaround at various levels of production. This makes it great for prototyping since it can be used for small runs or test runs before creating dies for an extensive production schedule.

Lasers can be used for more than just cutting, too. As a part of the production process, lasers can be used for:

- Annealing: Altering a materials physical state or its chemical makeup with heat treatment

- Drilling: Holes and slots

- Engraving: Personalised messaging, traceability etc.

- Etching: Making designs using strong acids

- Scoring: Partially cutting the material

- Perforating: Punching holes

On top of that, a laser can handle several processes at once - like cutting, marking, and engraving - without having to re-fixture the sheet of rubber.

Which rubber cutting method is the right one?

There are several factors that should be considered before choosing a cutting method:

- Material: What type of rubber material is being cut? The material’s characteristics will play a huge role in the type of cutting methods that can be used.

- Thickness: Certain cutting methods may be an overkill on materials that are too thin. Then again, if we are dealing with a high thickness, it will require very specific machines in order to continue producing quality cuts at a satisfactory rate.

- Production Rate: Some methods simply are not suited to production at higher speeds, or it is possible that the cuts will lose quality if the speed is pushed too high. When you need a certain level of production, make sure you are working with a die cutting partner that can handle high speeds and high quality.

- Special shapes: If you need something more than a basic shape, it may limit your options for cutting methods. Laser and water jets cutting, for example, can be used for intricate cuts, but will end up taking more time.

Thinking through these factors will greatly help you choose the cutting method that will produce the desired results in the most cost-effective manner.