Situation

As ‘Hannibal’ would say; “I love it when a plan comes together”. And we couldn’t agree more. At Walker Rubber we set out with a plan to become a dedicated, high-quality and sought-after rubber manufacturer that our customers can rely on. We made this our mission at the very beginning of our journey as a rubber company. The plan of action to achieve this, was to try our very best to improve and expand our business practices no matter what curveballs were thrown at us, be it economic recessions, war times, pandemics and the list goes on.

We want to be the rubber company that is first on the mind of the consumer and this is being realised especially in a local capacity. This is courtesy of our decades of experience working with a multitude of different industries. In this “Case in Point”, a company of vehicle body builders and converters require a cost-effective solution that could lessen and outright eliminate the possibility of damaging their vehicles.

Our paths were soon to cross and once they identified there was a problem with their vehicles, they asked their affiliates if they could recommend anyone, and this is where our name came into the mix. Walker Rubber was highly recommended as a reliable and cost-effective rubber manufacturer and supplier. The vehicle converters decided to listen to their friend's advice and called us. So, what was the problem?

Problem

The vehicle bodybuilders and converters specialise in converting delivery vehicles for supermarkets. They install refrigerated and temperature-controlled storage areas for vans and trucks. These vehicles are driven on a daily basis and must be maintained frequently to ensure the foodstuffs and items being delivered to the general public are in compliance with the legal and ethical requirements.

They discovered quickly that the rear doors of these supermarket delivery vehicles were suffering unnecessary wear and tear. Supermarkets send vehicles to make millions of deliveries to households nationwide, 7 days a week. The rear door hinge has a plastic bump stop which is designed to cushion the impact of the door being closed, protecting the locking mechanisms.

The plastic bump-stops were buckling under the pressure, snapping after weeks, even days of being applied to the rear door hinge. To begin with their attitude towards this was that they were cheap and easy to replace, but as the breakages piled up in a such a short amount of time, it became apparent that the plastic bump stops weren’t fit for purpose. If you take into consideration these doors are being opened and closed nearly 100 times a day the plastic couldn’t measure up to the task. They needed a better option.

They reached out to their friends, partners and local businesses whom for other options which led them to looking for rubber companies and we were highly recommended in the Norfolk community. Rubber offers a high rate of compression, something plastic cannot do as it lacks elasticity. After some deliberation, they took the local consensuses advice and got in contact with us. We had a very productive discussion and helped in any way we could.

Solution

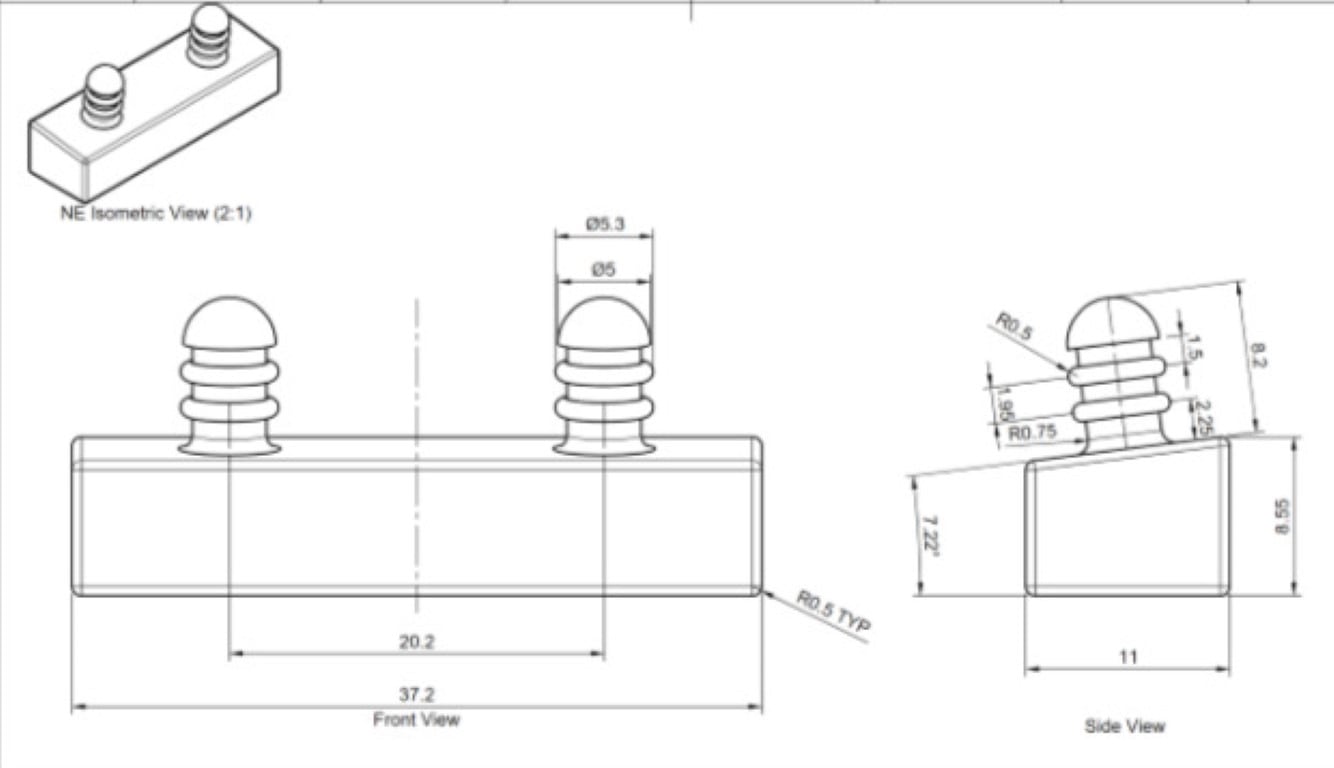

Our client brought us a sample of the bump stop as well as a design and we offered our insight on how our rubber could help protect the locking mechanism and the door. Rubber has elasticity or the ability to reform, whereas plastic when faced with too much pressure will deform. We gave them a quote, and the next day they requested 2500 bump stops.

The bump-stops were manufactured, packaged and collected with no issues in the production process. Our customer was impressed with our work and has expressed an interested in working with us again for future projects. We think that speaks volumes and shows why we are at the forefront of business minds when they require a rubber manufacturer. It’s been a long time coming and we’re continuing to improve and becoming more visible to viable businesses.

Final Thoughts

We were approached by vehicle converters/bodybuilders who primarily transform vans into delivery transport for supermarkets. They were getting several recalls because the rear door bump stops were breaking off. After this became too frequent, they looked for another solution and this is where we came in. They reached out to local companies and partners who recommended us.

After a lengthy discussion we established what our new customer needed. The next day they personally came to our factory with a sample and CAD drawing. We then took that design and created the bump stop for them, once they were happy with the product, we quoted them for 2500 bump stops. These were manufactured quickly and delivered within the expected lead times.

Looking forward, our customer is very happy with our service and he rubber bump stops are doing the job, withstanding the pressure from opening and shutting the rear door. As for our relationship with our customer, we will be working closely together on future projects.

We’re incredibly grateful for anyone who recommends us as it’s living proof that our hard work is paying off. If you think our knowledge and expertise can help you, then please get in touch, we are looking forward to hearing from you.

If you’re looking for bump stops then you’re just a click away.

We hope you enjoyed this edition of "Case in Point" and until then, we’ll see you at the next one.