The Situation

At Walker Rubber, we are approached by multiple companies of all different shapes and sizes for a variety of jobs and projects. As a rubber manufacturer, we get our fair share of quirky projects from very niche markets.

In this instance, we were approached by carriage restorationists. Their job is to bring age-old carriages and vehicles of yesteryear, back to life, restoring them to their former glory.

This is a family run business which began in the 1970s. It has since been passed on to their next of kin who have vowed to continue the work of their predecessors. The carriages restored, hark back to the 1800s, some of which are the last of their kind. This company endeavours to restore these carriages to a better state than when they were first introduced to the general public.

Our sales team received an email enquiring about a bespoke grey cab tyre extrusion for an 1896 Peugeot carriage. We reached out to the company to see what they required, and they really wanted the grey cab tyre to look as close to the original as possible. To make sure they were happy with the colour, we offered to send a sample of the grey EPDM, which they accepted.

What was the problem?

Cab tyres are by no means an overly popular product we produce on a daily basis, but we have extruded a few in our time. There are multiple companies we work with who also require these kinds of parts, so this wasn’t our first rodeo. Our experience will definitely come into play here. This was a first-time customer, so we wanted to make sure that we made a good first impression and hopefully convert them into repeat customers.

We requested any additional information and measurements to makes sure we knew exactly what our potential new customer wanted. They wanted, a cab tyre to emulate exactly how it looked like in the 1800s. This included the colour of the tyre which they needed in grey.

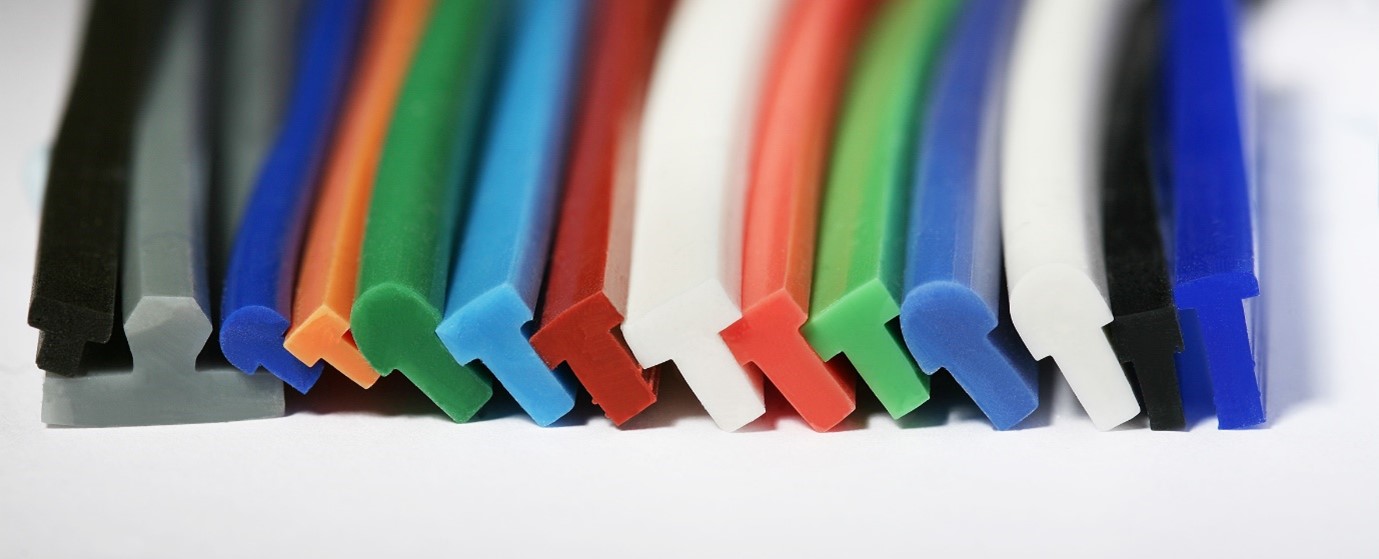

It’s much easier to source different colour rubbers as the art of changing the colour of rubber is a very technical and time-consuming job. We were able to specially source a grey compound of EPDM. We cut a sample and sent it to the restorationists to see if this was the correct shade of grey, they were looking for.

How was the problem solved?

We were quick to receive a response from our customer giving us the all-clear. Their customers were happy with the colour we sourced. This enabled us to quote the order thus, winning the sale. The company sent through their bespoke profile design on AutoCAD and we were able to create an extrusion profile that was as close to their sample as we possibly could.

Next, we used their bespoke profile design to extrude the cab tyre. The extrusion was then coiled to sit comfortably in the autoclave. The cab tyre went through the vulcanisation process and then was removed from the autoclave and left to cool.

Once at a cooler temperature, the cab tyre was wrapped and packaged securely for delivery. The order was dispatched on the approval date. Our sales team worked diligently, helping our customer throughout the process and they were very happy with the finished product.

Final Thoughts

We were approached by a vehicle restoration company who return old period vehicles to prominence. Their customer needed a grey rubber cab tyre for an 1896 Peugeot carriage which would require a grey rubber extrusion. The restorationists got in contact via email with their dilemma. This isn’t a common job that we come across frequently however, we do have experience in the past producing cab tyres for other customers.

This was yet another opportunity for us to turn heads and get another repeat customer. After reaching out to suppliers we saved time by sourcing grey EPDM. Once this arrived at our factory, we sent through a sample for their customers to assess. Once we were given the go ahead, we went on to design an extrusion profile for the cab tyre that was as close to its original as possible.

We experienced no issues with our processes, we managed to supply and manufacture the cab tyre with no issues. The order was despatched on time without any delays. This project was incredibly fascinating for us. Our customer was taking old technology and incorporating newer technology to rejuvenate refurbished 150-year-old vehicles.

Synthetic rubber EPDM wasn’t invented by DuPont till the 1950’s, so it's like we’re breathing new life into the carriage. We pride ourselves on being trusted advisors that can help our customers with any issues regarding rubber.

If you think we can help you then please get in touch, and we will endeavour to assist you in any way we can. You would be surprised what random projects we’ve taken on throughout the decades as a rubber manufacturer.

One thing that will forever set us apart from most competitors, namely resellers, is that we can machine tool a bespoke extrusion profile. Check out our capabilities here.

Also, if like this company, you’re in need of a cab tyre, then we are the place to come to, we look forward to receiving your quote.

As always. we have been Walker Rubber, and we’ll see you at the next ‘Case in Point’.