Rubber Bonding & Fabrication

Delivering rubber bonding in industry leading delivery times

Walker Rubber is capable of bringing your rubber bonding ideas to the forefront. Take a chance on us and we will deliver.

Walker Rubber’s bonding process will meet your needs in no longer than two weeks. We offer some the most unique products like our Fire fighters pole mat and Horse box ramp mat.

Do you require an extra-large gasket bonded together in sections? Or perhaps you’re looking for a unique rubber/foam/rubber laminate material offering extra wear-resistance whilst maintaining a cushion? If you supply us with your design, we will endeavour to find a solution.

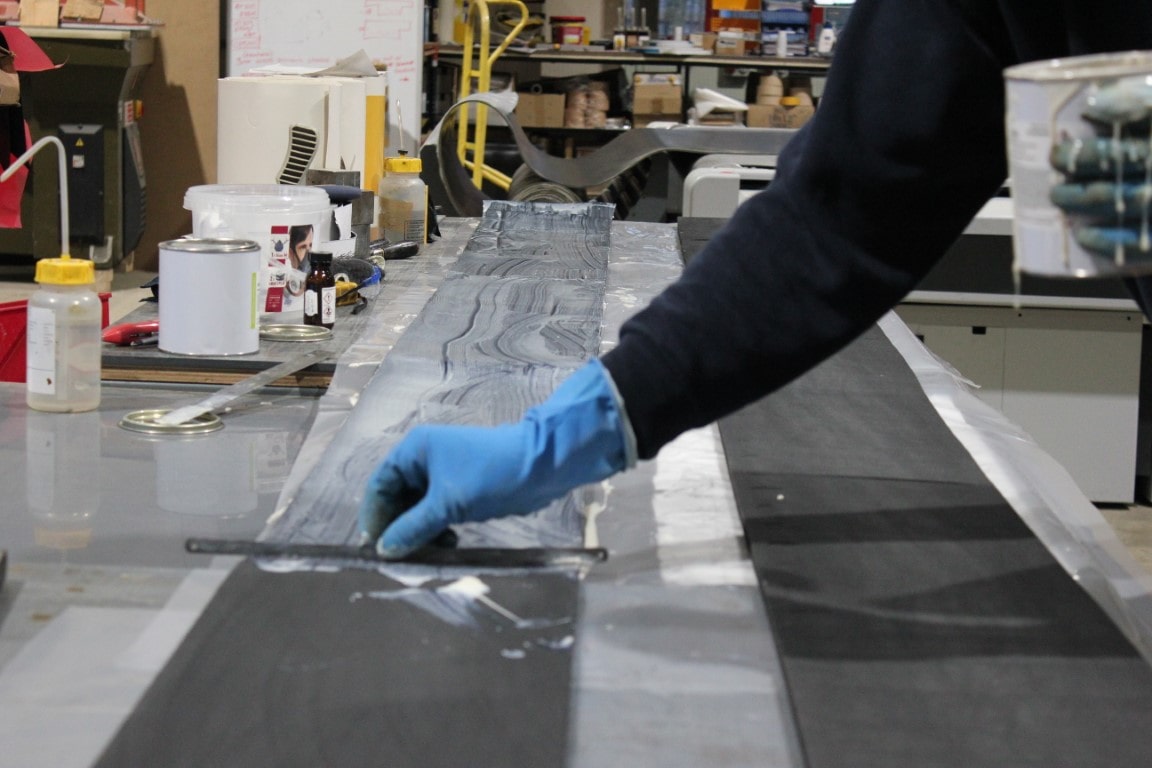

Bonding does not have to be constrained to materials we supply. We are also capable of bonding our rubber to metal. Alongside our ability to bond rubber to metal we can also bond all our rubber materials to a variety of other supplied materials.

Our 80 years of knowledge combined with our state-of-the-art equipment ensures we will not to be bested on quality and lead times.

Our rubber bonding combinations

At Walker Rubber we pride ourselves on our ability to bond rubber to a wide range of materials. Being able to do this allows for a variety of possibilities for our customers to find the right solution. Some of our most popular combinations are:

- Rubber-to-rubber bonding, create the possibility for a range of thickness that are different to the standard sheet range.

- Rubber-to-foam bonding

- Rubber matting-to-foam bonding

- rubber-to-metal bonding (commonly mild steal)

- foam-to-metal bonding (commonly mild steal)

The rubber materials that we commonly use to bond include:

Our rubber bonding combinations

At Walker Rubber we pride ourselves on our ability to bond rubber to a wide range of materials. Being able to do this allows for a variety of possibilities for our customers to find the right solution. Some of our most popular combinations are:

- Rubber-to-rubber bonding, create the possibility for a range of thickness that are different to the standard sheet range.

- Rubber-to-foam bonding

- Rubber matting-to-foam bonding

- rubber-to-metal bonding (commonly mild steal)

- foam-to-metal bonding (commonly mild steal)

The rubber materials that we commonly use to bond include:

The Walker Rubber Difference

Delivery

Rubber bonded products manufactured to order with industry leading turnaround times. Bonding can be a longer process than our other services with a realistic delivery time of 5-10 days. It’s important that your product is fully set prior to despatch.

Support

Not quite sure what you need? Our team are on hand to provide fast, high-quality expertise with years of experience to back it up.

Service

Our sales team will guide you through the process every step of the way. We are proud to say 90% of enquiries are quoted on the same day ensuring there is no delay.

Quality

With our right first-time ethos, combined with only using premium materials from trusted sources, the quality of our rubber bonded products are the best in the business.

Learn More About Bonding Rubber

Our knowledge hub is packed with information to help you in your next project! Visit the page below to get a more in-depth look at bonding rubber.

Bonding rubber Rubber adhesives