Situation

One thing we have learned in our many decades working in the rubber industry is to expect the unexpected. You never know who the next customer is going to be. We’ve had the pleasure of working on many weird and wonderful projects over a wide spectrum of industries. Being part of this, has further improved our experience and expertise in advising customers on what rubber best suits their applications.

We want our customers to succeed and if we can help them with their problems, we will jump at the opportunity to do so. Sometimes, we receive enquiries from organisations and institutions that don’t strike us as a place that needs manufactured rubber, and this is one of those instances.

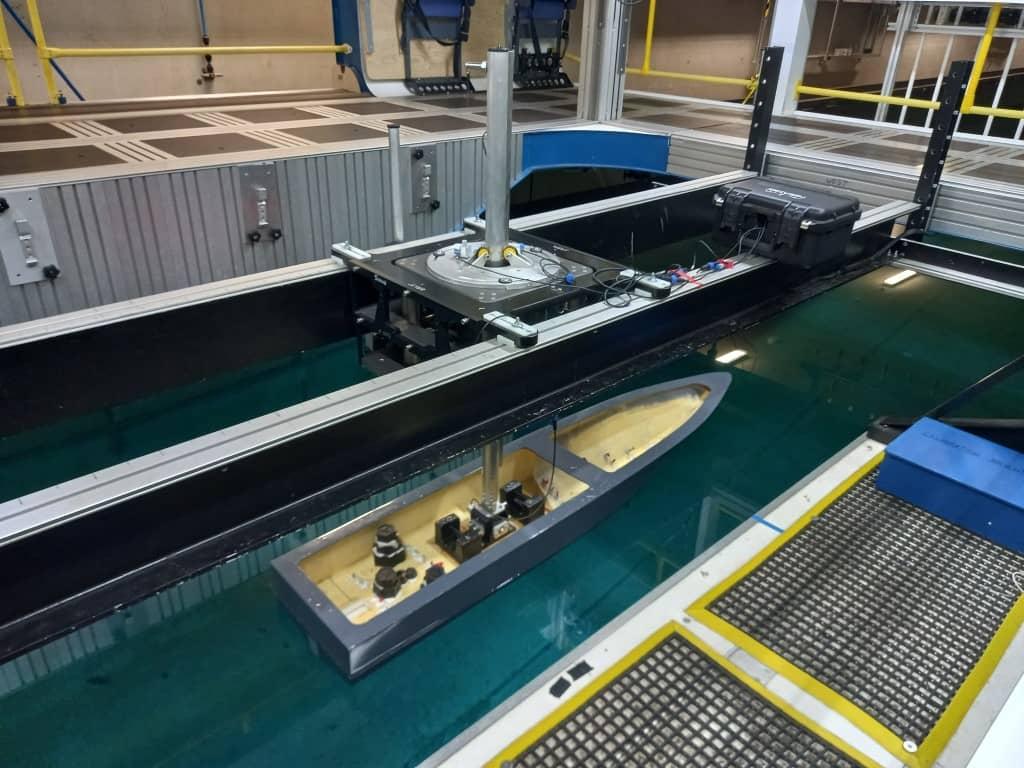

In one of our most technical “Case in Point’s” to date, we are called into action to help an educational institution who are experiencing issues conducting simulations with their towing tank. This university has the honour and bragging rights for having the largest towing tank in the United Kingdom, 138 metres in length to be exact. Researchers and commercial participants from marine, aerospace and transportation backgrounds come from far and wide for a chance to use this application.

Problem

The towing tank is a laboratory used to test scale models of boats, ships and static objects. The models are pushed through the tank by a moving carriage that runs at a preset speed. The model boat or object’s telemetry is captured by a data recording system which gives the researchers insight as to how a 1:1 scale version would fare in the grand blue. A shipbuilders dream!

Their problem occurred when the towing tank was paired with the wavemaker machine. The wavemaker does exactly as it says on the tin and sends ripples and waves through the towing machine however, due to a gap in the tank, cross waves were being formed and disrupted their testing results.

Inside the towing tank, there are side beaches designed to dampen the waves as they rush through the tank ensuring that the best results can be recorded. The gap between the side beach panel and the face of the tank was big enough for the water to build up and then send a cross wave back at the model.

They couldn’t test the models, prototypes and static objects properly and needed to fill the gap stop these cross waves from disrupting the simulations. To rectify this, the head technician contacted us to see if we could design and manufacture a rubber seal that could fill that area and enable the side beeches to dampen the incoming waves.

Solution

The University got in touch with us looking for a large L section extrusion t fill the space between the side beaches and the wall. Our sales team sprang into action and consulted with the customer to fully understand the situation.

After receiving the enquiry it was clear to the sales team that, this job would require a bespoke rubber extrusion due to its size. We quoted the university for our machine tooling capabilities and for the L section rubber seal, they were familiar with our competitive prices and our ‘no minimum order’ policy and quickly made the transaction.

We reverse engineered their bespoke template and extruded their rubber seal. The seal was then cut to size and put into the autoclave for curing. We then conducted our routine quality control checks making sure the measurements were correct before the order was packaged and dispatched.

Upon receiving and attaching the rubber seal, the university was pleased with the result as they could conduct their sea-fearing tests without any disruptions or discrepancies to their data. They also expressed an interest in including us in future projects. Which we’re very much looking forward to, as you readers should know by now, we relish a challenge.

Final Thoughts

A university reached out to us in need of a seal for their towing tank which they use to test prototype models of ships, boats and static objects. They do this to see how well a real-life version of these models would measure up on the deep blue seas. To fully simulate a seafaring experience, they pair the towing tank with a wave machine which sends ripples towards the model. The towing tank is 138 metres long so there is plenty of space to record the necessary measurements, however they were experiencing issues throughout the testing stage.

During the test, the models were getting hit by cross waves caused by a gap between the side beaches and the wall. The beaches are designed to dampen the waves, but the gap created a build-up of water that rebounded into the side of models making it difficult to record reliable data.

After discussing what was required, we machine-tooled a new bespoke profile for our customer and then extruded and cut the rubber to the specific measurements. The order was then vulcanised in the autoclave, checked and dispatched to the university. To the delight of our customers, this was a fast turnaround time which enabled them to use the perfect combination of tank and waves to test out these models once again.

We are looking forward to working with this customer again. It was a pleasure to help out this institution when they really needed it, and we could do this for you too.

If you’re in need of any manufactured rubber products then please get in touch, our sales team are here to help you.

That brings another “Case in Point” to a close. Be sure not to miss the next installment as we could well be talking about your order.

If you enjoyed reading this, there are many more for you feast your eyes upon right here.

Until next time, we’ve been Walker Rubber.

See you at the next one.