Moulding Rubber Parts

What is rubber moulding?

Rubber moulding is a process that takes raw rubber material and turns it into a product of the desired 3D geometry. Due to rubber being incredibly elastic, it is a very popular material for mouldings in industrial applications. These include:

Rubber mouldings that serve the purpose of reducing vibration and noise:

- Rubber Bumpers

- Bushings

- Pads

- Isolators

Preventing leaks and friction:

- Rubber diaphragm

- O-rings

- Seals

To reduce damage between interacting components:

- Rubber grommets

- Plugs

Providing support:

- Rubber mounts

Handling and manipulating items with flat surfaces:

- Rubber suction cup

Distibuting load:

What are the different types of rubber moulding?

Three commonly used types of moulding are:

- Compression moulding

- Injection moulding

- Transfer moulding

There is also blow and vacuum moulding, however, this is conducted most of the time on plastics.

Multiple rubber moulding processes have been devised over the years as a result of unique manufacturing situations. These processes have different requirements and limitations.

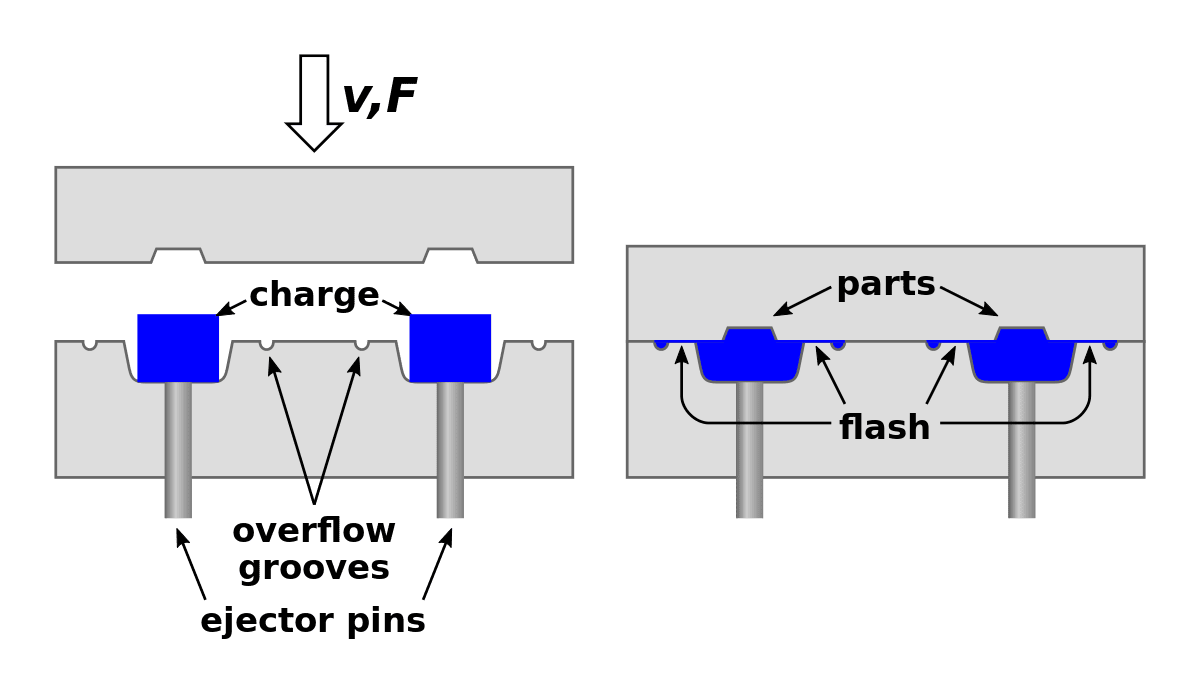

What is compression moulding?

Compression moulding is the oldest and simplest of the three methods. Unvulcanised rubber is placed into a two-part clamshell style mould which is then closed and heated. As the rubber in the mould heats up, it expands and fills the mould cavity. When the correct pressure and temperature are reached, the rubber vulcanises or cures, meaning the rubber will keep its shape as it cools and is removed from the mould.

What are the advantages of compression moulding?

The benefits of using compression moulding are:

- Less wastage

- Less technical and less drain on money and resources than injection moulding.

- Recommended for parts with large cross-sectional areas

- Easier to process highly durable and robust rubber. Due to its increased capacity.

The disadvantages of compression moulding are:

- Difficult to retain a level of consistency with finished parts

- Takes longer than other processes

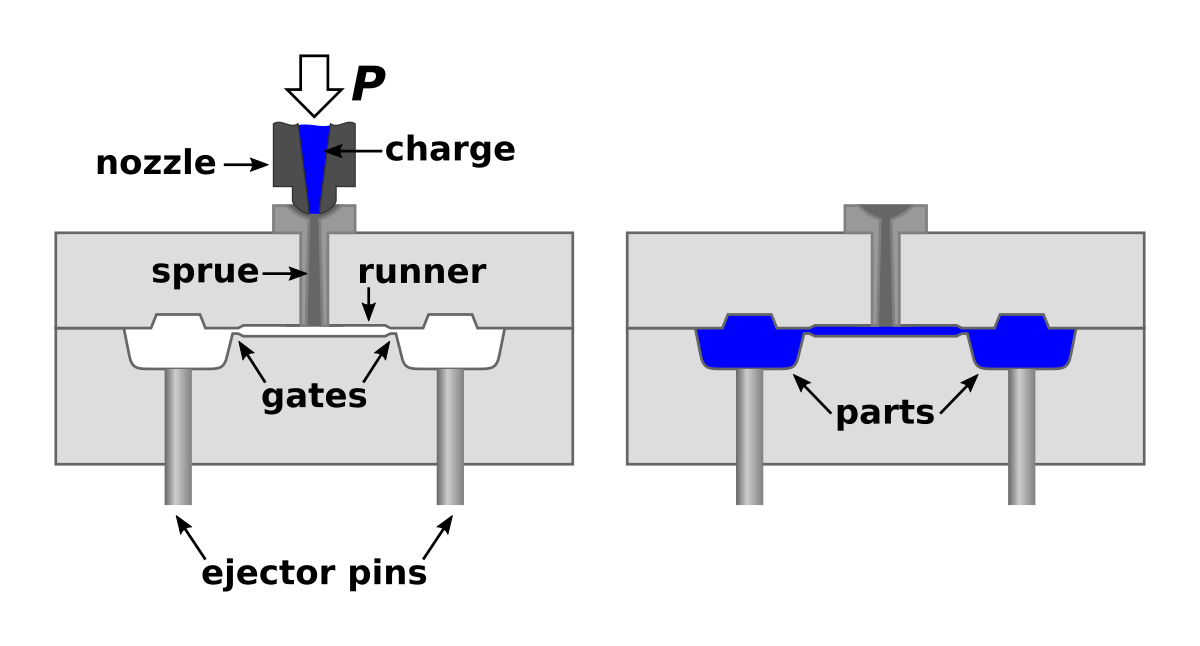

What is injection moulding?

The injection moulding process is used to produce products that require tight tolerances with high precision and accuracy. Raw rubber is heated until it is molten, meaning that it will flow easily into the mould cavity. The rubber is supplied to the mould through a nozzle and barrel assembly that provides a continuous flow. The preheating process shortens curing time and allows for higher curing temperatures. Loss of material, or flash, is limited by tightly clamping the mould. The liquified rubber fills the mould cavity and packs tightly to the walls of the mould to form the desired shape as shown in the diagram below. Originally this method was limited to the plastic industry. In the 1960s, manufacturers started to use this method for rubber parts as well.

What are the advantages of injection moulding?

There are a range of benefits that come from rubber injection moulding, such as:

- Waste minimisation

- Quick rollout times

- Speedy production

- High dimensional tolerances

However, as with any manufacturing process, there are some disadvantages:

- Setup can be expensive

- Tooling limitation and design capabilities

- The need for expensive tooling and machinery

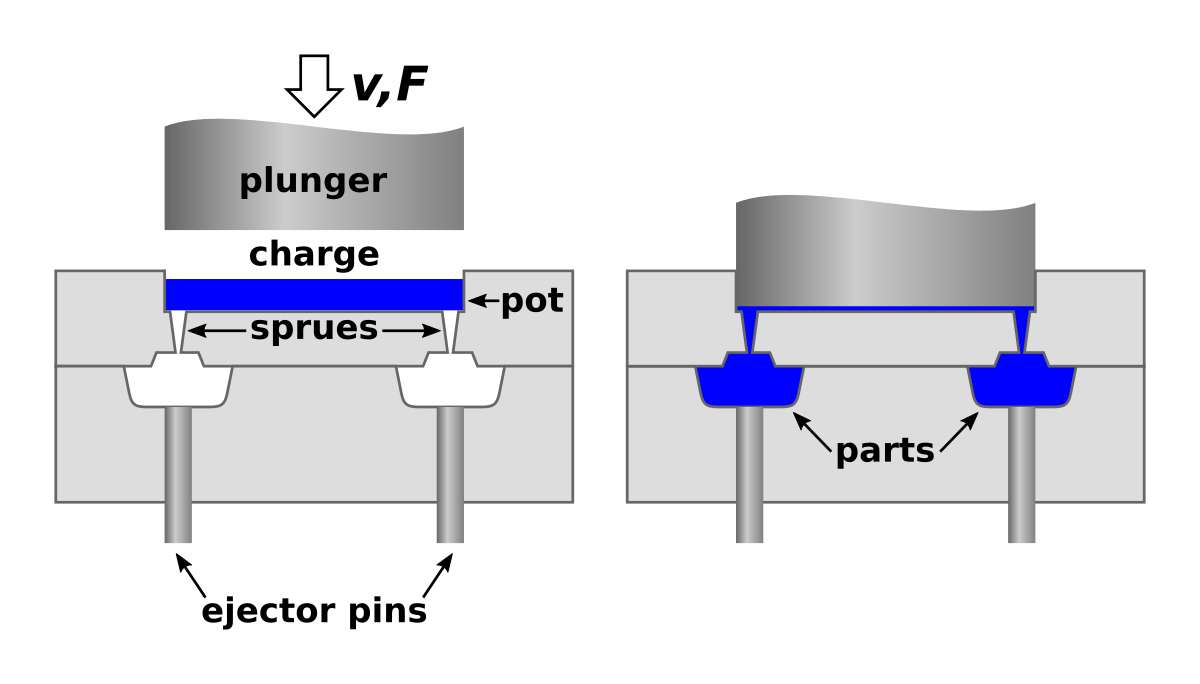

What is transfer moulding?

Transfer moulding has similarities to both compression moulding and injection moulding. Initially, the unvulcanised material is compressed, very much like compression moulding. The compression forces the material through a small channel into multiple closed moulds which moulds the part, like injection moulding. Transfer moulding is a highly efficient process with short tool loading times. The process allows for high production runs though parts do not have tight tolerances. The material cures during the process, after which the mould is split, and the parts are released.

What are the advantages of injection moulding?

The advantages of transfer moulding are:

- Greater accuracy than compression moulding

- Short manufacturing process

The disadvantages of transfer moulding are:

- Potential rise in material wastage

- Maintenance and repairs can be time-consuming

- Designing detailed and technical parts can be costly

What materials are used for rubber moulding?

Natural rubber, nitrile, or buna-N (NBR), hydrogenated nitrile butadiene (HNBR), ethylene propylene diene monomer (EPDM), silicone, fluorosilicate (FVMQ), neoprene, styrene butadiene (SBR), fluorocarbon (FKM), butyl or isobutylene isoprene (IIR), urethane - these are all the rubbers that can be used in the rubber moulding processes, which has enabled manufacturers to create a huge variety of moulded rubber products.